Stainless Steel Flanges manufacturer in India

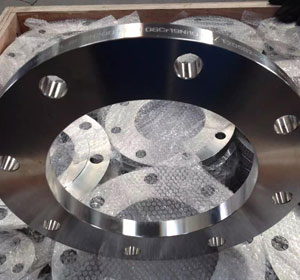

Exporter of Stainless Steel Forged and Plate Flanges in Mumbai in all types and pressure class.

Stainless Steel Flanges Manufacturer In India

ASTM A182 SS Pipe Flanges

Large Diameter Stainless Steel Flanges

Table of contents

- What Is A Stainless Steel Flange?

- ASTM A182 SS Flanges Different Type Use In Pipeline?

- What Use Of Large Diameter Stainless Steel Flanges Hydraulic Systems?

- ASTM A182 Standard Specification

- Class 150 Stainless Steel Flange Dimensions

- Class 300 Stainless Steel Flange Dimensions

- Metric SS Flange Temperature Pressure Rating

- Stainless Steel Flange Weight Chart AS Per ASME B16.5

- ANSI B16.5 SS Flanges HS Code

- Industrial Pipe Flanges Heat Treating Requirements

- Stainless Steel Stub End Flanges Chemical Requirements

- SS Header Flanges Mechanical Requirements

- High Pressure Stainless Steel Flanges Thickness Calculation

- SS Flanges Bolt & Stud Chart

- Gaskets For ASTM A182 Stainless Steel Flanges

- SS Forged Flanges Tolerances

- Reliable Types Stainless Steel Flange Manufacturer In India

What is A Stainless Steel Flange?

Our Stainless Steel Pipe Flanges conform to the standards with different faces and pressure classes. Our Stainless Steel Exhaust Flanges are suitable for connection with exhaust pipe and manifold system. Stainless Steel Header Flanges make it viable for the exhaust systems to be connected to the cylinder head. Stainless steel flange manufacturers in India produce different types of flanges. We produce different types of flanges.

ASTM A182 SS Flanges Different Type Use In Pipeline?

Stainless Steel Screwed Flanges are the ones with a screwed connection type that has threads in the bore. In places where the piping cannot be disassembled, the Stainless Steel Split Flanges can be used in two pieces to fit them together. Stainless Steel Square Flanges are commonly used in a pipe to component basis where they give an excellent hold with the component. We supply different pressure classes of flanges. For example the ANSI 150 Stainless Steel Flanges that belong to the Stainless Steel Class 150 Flanges and other classes are available from us. Santosh Pipe Fitting is one of the leading stainless steel flange manufacturers in India.

What Use Of Large Diameter Stainless Steel Flanges Hydraulic Systems?

AWWA Stainless Steel Flanges are used mostly in water services. In applications where high pressures are possible like in hydraulic systems, the High Pressure Stainless Steel Flanges are used. In water supply and other larger supply volumes, the Large Diameter Stainless Steel Flanges are used to connect larger pipes. For applications which require thin and light weight pipes, the Metric Stainless Steel Flanges are used. In complex systems where multidimensional pipes are interconnected, our Stainless Steel Reducing Flanges are handy. SS Flanges come with different forms and faces such as Stainless Steel Raised Face Flanges and others. There are different standards by which the dimensions are governed. Pn16 Stainless Steel Flanges for example are governed by DIN 2501 and ISO 7005 standards.

Check ASTM A182 SS Flanges Pressure Rating, Weight Chart, and Dimension, view Large Diameter Stainless Steel Flanges price in Mumbai.

ASTM A182 Standard Specification

| Material Specification Of : | Stainless Steel Flanges |

|---|---|

| Standard Cover : | pressure ratings & temperature ratings, materials, marking, dimensions, weight, tolerances, testing |

| Contact Faces | RTJ (Ring Type Joint), FF (Flat Face), RF (Raised Face), T/G (Tongue And Groove ), M/F (Male And Female) |

| Size Chart | Normal Pipe Size 1/2 to NPS 24" |

| Thickness | Normal Pipe Size ≤ 18 |

| Bore Diameter | Normal Pipe ≤ 10 |

| Flanges Standards | EN 1092-1, JIS, ASME B16.5, ASME B16.47 type A, UNI, DIN |

| Pressure Rating | Class 150 To Class 2500 |

| High Temperature | Above 200°C (400°F) For Class 150 Or Above 400°C (750°F) |

| Low Temperature | Above -29 Degree C (−20°F) |

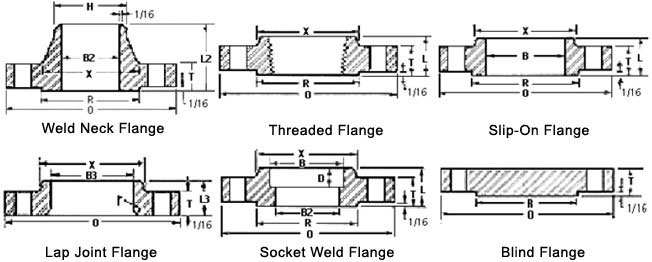

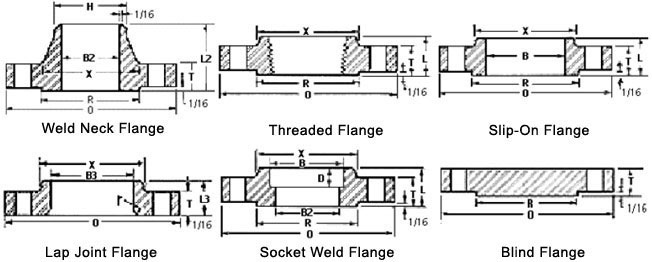

| Common Types Of Flanges: | Slip On (SORF), Weld Neck (WNRF), Blind (BLRF), Lap Joint (Loose), Threaded (NPT), Socket-Weld (SWRF) |

| Special Types Of Flanges : | Nipoflange, Elboflange, Latroflange, Swivel Flange, Expanding Flange, Reducing Flange, Weldoflange |

| Marking Standard | Name of Manufacturer Schedule Type of Flange Facing Nominal Pipe Size Pressure Class ASME B16 Designation |

| Bolt Type | high strength bolts medium strength bolts low strength bolts |

| European Standard Flanges | JIS B2220 Flanges (5k to 30k) and KS1503 flanges |

| Russian-Standard Flanges | GOST 12820 / 12821-80, DIN, UNI, EN 1092-1 |

| South African Standard Flanges | SANSflanges And SABS flanges |

| Surface Finish | smooth, concentric serrated, stock |

| Gaskets Types | Full Face Gasket Flat Ring Gasket Metallic Ring Gakset |

| Advantages Of Pipe Flange | Used to Connect Pipe System Easy Repair Pipe System Assembled Without Welding |

Wide Variety Of Bulk Stainless Steel Stub End Flanges And View ASME B16.5 SS Flange Price List India.

Class 150 Stainless Steel Flange Dimensions

| NPS | O.D. of Flange | Flanges Thickness | Diameter of RF | Diameter of Hub at Base | Lengtd Tdru Hub | Bore or Diameter | Dia. of Hub at Bevel | Radius of Fillet | Deptd of Socket | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Welding (WN) Neck | Slip-On (SORF) Threaded (NPT) Socket (SWRF) | Lap Joint (Loose) | Slip-on (SORF) Socket (SWRF) | Lap Joint (Loose) | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.20 | 18.00 | 1/2 | 1-15/16 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | 20.20 | 20.25 | 20.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

Class 300 Stainless Steel Flange Dimensions

|

NPS

|

(O.D.) of

flanges |

Min.

thickness of flanges |

Overall Length

|

Bolt Circle

(BC) |

Number and

Sizes of Holes |

Outside Daimeter of

raised face (RF) |

|||

|

Weld

neck (wn) |

Slip-on (sorf)

& socket (swrf) welding (wn) |

Lap Joint (Loose)

|

|||||||

|

O

|

Q

|

Y

|

Diameter

|

Number

|

Diameter

|

R

|

|||

|

1/2

|

95

|

14.3

|

52.4

|

22.2

|

22.2

|

666.5

|

4

|

15

|

35

|

|

3/4

|

117

|

15.9

|

57.2

|

25.4

|

25.4

|

82.4

|

4

|

19

|

43

|

|

1

|

124

|

17.5

|

61.9

|

27.0

|

27.0

|

89.0

|

4

|

19

|

51

|

|

1-1/4

|

133

|

19.1

|

65.1

|

27.0

|

27.0

|

98.5

|

4

|

19

|

64

|

|

1-1/2

|

156

|

20.7

|

68.3

|

30.2

|

30.2

|

114.5

|

4

|

22

|

73

|

|

2

|

165

|

22.3

|

69.8

|

33.3

|

33.3

|

127.0

|

8

|

19

|

92

|

|

2-1/2

|

190

|

25.4

|

76.2

|

38.1

|

38.1

|

149.0

|

8

|

22

|

105

|

|

3

|

210

|

28.6

|

79.4

|

42.9

|

42.9

|

168.0

|

8

|

22

|

127

|

|

4

|

254

|

318

|

85.7

|

47.6

|

47.6

|

200.0

|

8

|

22

|

157

|

|

5

|

279

|

35.0

|

98.4

|

50.8

|

50.8

|

235.0

|

8

|

22

|

186

|

|

6

|

313

|

36.6

|

98.4

|

52.4

|

52.4

|

270.0

|

12

|

22

|

216

|

|

6

|

381

|

413

|

111.1

|

61.9

|

91.9

|

330.0

|

12

|

25

|

270

|

|

10

|

444

|

47.7

|

117.5

|

66.7

|

95.3

|

387.5

|

16

|

29

|

324

|

|

12

|

521

|

50.8

|

130.2

|

73.0

|

101.6

|

451.0

|

16

|

32

|

381

|

|

14

|

584

|

54.0

|

142.9

|

76.2

|

111.1

|

514.5

|

20

|

32

|

413

|

|

16

|

648

|

57.2

|

146.0

|

82.6

|

120.7

|

571.5

|

20

|

35

|

470

|

|

18

|

711

|

60.4

|

158.8

|

88.9

|

130.2

|

628.5

|

24

|

35

|

533

|

|

20

|

775

|

63.5

|

161.9

|

95.2

|

139.7

|

686.0

|

24

|

35

|

584

|

|

24

|

914

|

69.9

|

168.3

|

106.4

|

152.4

|

843.0

|

24

|

41

|

692

|

We Provide Stainless Steel Mechanical Joint Flange For Pipe Connection And SS Pipe Flanges Equivalent Length Of Flanges.

Metric SS Flange Temperature Pressure Rating

| ASME B16.5 Stainless Steel Flanges | Pressure Rating Chart | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

Stainless Steel Flange Weight Chart AS Per ASME B16.5

| Nominal Pipe Sizes (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (Loose) | Blind (BLRF) | Weld Neck (WRNR) |

|---|---|---|---|---|---|---|

| ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 |

ANSI B16.5 SS Flanges HS Code

| HS Code | Item Description | Policy |

|---|---|---|

| 73 | Iron or Steel | |

| 7307 | Tube Or Pipe Fittings (for Example, Couplings, Elbows, Sleeves), Of Iron Or Steel - Cast Fittings : | |

| 73072100 | Other, of stainless steel: Flanges | Free |

| Free | ||

Industrial Pipe Flanges Heat Treating Requirements

| Gr. | Heat | Austenitizing And Solutioning | Cooling | Quenching | Tempering | ||

| treat type | Temperature, minimum °F | Media | Cool | Temperature | |||

| Stainless Steel 304 Flanges | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| Stainless Steel 304H Flanges | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| Stainless Steel 304L Flanges | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| F 304N | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| F 304LN | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| Stainless Steel 310H Flanges | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| Stainless Steel 310 Flanges | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| Stainless Steel 310H Flanges | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| F | Solution | 1900-2010 [1050-1100] | Liquid | 500 [260] | B | ||

| 310MoLN | treat and | ||||||

| quench | |||||||

| Stainless Steel 316 Flanges | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| Stainless Steel 316H Flanges | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| Stainless Steel 316L Flanges | Solution | 1900 [1040] | Liquid | 500 [260] | BB | ||

| treat and | |||||||

| quench | |||||||

| F316N | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| F 316LN | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| F316Ti | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| Stainless Steel 317 Flanges | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| Stainless Steel 317L Flanges | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| S31727 | Solution | 1975-2155 [1080-1180] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| S32053 | Solution | 1975-2155 [1080-1180] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| F347 | Solution | 1900 [1040] | liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| F 347H | Solution | 2000 [1095] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| F 348 | Solution | 1900 [1040] | Liquid | 500 [260] | B | ||

| treat and | |||||||

| quench | |||||||

| F 348H | Solution | 2000 [1095] | Liquid | 500 [260] | BB | ||

| treat and | |||||||

| quench | |||||||

| Stainless Steel 321 Flanges | Solution | 1900 [1040] | Liquid | 500 [260] | |||

| treat and | |||||||

| quench | |||||||

| Stainless Steel F321H Flanges | Solution | 2000 [1095] | Liquid | 500 [260] | B | ||

| treat and | |||||||

Stainless Steel Stub End Flanges Chemical Requirements

| Material Symbol | C | Mn | P | S | Si | Ni | Cr | Mo | Cu | N | V | Co |

| Stainless Steel 304 Flanges | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-11.0 | 18.0-20.0 | |||||

| 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0-13.0 | 18.0-20.0 | ||||||

| Stainless Steel 316 Flanges | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-14.0 | 16.0-18.0 | 2.00-3.00 | ||||

| Stainless Steel 316L Flanges | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-15.0 | 16.0-18.0 | 2.00-3.00 | ||||

| Stainless Steel 321 Flanges | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 9.0-12.0 | 17.0-19.0 |

SS Header Flanges Mechanical Requirements

| Material Symbol | Tensile Strength, minimum, MPa | Yield point, minimum, Mpa | Elongation, minimum, % | Reduction of area, minimum, % | Hardness, maximum, HB | Minimum Impact Average, J |

Test Temp, °C |

| Stainless Steel 304 Flanges | 515 | 205 | 30 | 50 | |||

| Stainless Steel 304L Flanges | 485 | 170 | 30 | 50 | |||

| Stainless Steel 316 Flanges | 515 | 205 | 30 | 50 | |||

| Stainless Steel 316L Flanges | 485 | 170 | 30 | 50 | |||

| Stainless Steel 321 Flanges | 515 | 205 | 30 | 50 |

High Pressure Stainless Steel Flanges Thickness Calculation

| Stainless Steel Flanges Wall Thickness | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS (Normal Pipe Sizes) | Outside Daimeter (O.D.) | Schedule 10 | Schedule 20 | Schedule 30 | STD Wall | Schedule 40 | Schedule 60 | EXT Hvy | Schedule 80 | Schedule 100 | Schedule 120 | Schedule 140 | Schedule 160 | XX Hvy |

| ½ | 0.84 | 0.083 | ... | ... | 0.109 | 0.109 | ... | 0.147 | 0.147 | ... | ... | ... | 0.188 | 0.294 |

| ¾ | 1.05 | 0.083 | ... | ... | 0.113 | 0.113 | ... | 0.154 | 0.154 | ... | ... | ... | 0.219 | 0.308 |

| 1 | 1.315 | 0.109 | ... | ... | 0.133 | 0.133 | ... | 0.179 | 0.179 | ... | ... | ... | 0.25 | 0.358 |

| 1 ¼ | 1.66 | 0.109 | ... | ... | 0.14 | 0.14 | ... | 0.191 | 0.191 | ... | ... | ... | 0.25 | 0.382 |

| 1 ½ | 1.9 | 0.109 | ... | ... | 0.145 | 0.145 | ... | 0.2 | 0.2 | ... | ... | ... | 0.281 | 0.4 |

| 2 | 2.375 | 0.109 | ... | ... | 0.154 | 0.154 | ... | 0.218 | 0.218 | ... | ... | ... | 0.344 | 0.436 |

| 2 ½ | 2.875 | 0.12 | ... | ... | 0.203 | 0.203 | ... | 0.276 | 0.276 | ... | ... | ... | 0.375 | 0.552 |

| 3 | 3.5 | 0.12 | ... | ... | 0.216 | 0.216 | ... | 0.3 | 0.3 | ... | ... | ... | 0.438 | 0.6 |

| 3 ½ | 4 | 0.12 | ... | ... | 0.226 | 0.226 | ... | 0.318 | 0.318 | ... | ... | ... | ... | 0.636 |

| 4 | 4.5 | 0.12 | ... | ... | 0.237 | 0.237 | ... | 0.337 | 0.337 | ... | 0.438 | ... | 0.531 | 0.674 |

| 5 | 5.563 | 0.134 | ... | ... | 0.258 | 0.258 | ... | 0.375 | 0.375 | ... | 0.5 | ... | 0.625 | 0.75 |

| 6 | 6.625 | 0.134 | ... | ... | 0.28 | 0.28 | ... | 0.432 | 0.432 | ... | 0.562 | ... | 0.719 | 0.864 |

| 8 | 8.625 | 0.148 | 0.25 | 0.277 | 0.322 | 0.322 | 0.406 | 0.5 | 0.5 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 |

| 10 | 10.75 | 0.165 | 0.25 | 0.307 | 0.365 | 0.365 | 0.5 | 0.5 | 0.594 | 0.719 | 0.844 | 1 | 1.125 | 1 |

| 12 | 12.75 | 0.18 | 0.25 | 0.33 | 0.375 | 0.406 | 0.562 | 0.5 | 0.688 | 0.844 | 1 | 1.125 | 1.312 | 1 |

| 14 | 14 | 0.25 | 0.312 | 0.375 | 0.375 | 0.438 | 0.594 | 0.5 | 0.75 | 0.938 | 1.094 | 1.25 | 1.406 | ... |

| 16 | 16 | 0.25 | 0.312 | 0.375 | 0.375 | 0.5 | 0.656 | 0.5 | 0.844 | 1.031 | 1.219 | 1.438 | 1.594 | ... |

| 18 | 18 | 0.25 | 0.312 | 0.438 | 0.375 | 0.562 | 0.75 | 0.5 | 0.938 | 1.156 | 1.375 | 1.562 | 1.781 | ... |

| 20 | 20 | 0.25 | 0.375 | 0.5 | 0.375 | 0.594 | 0.812 | 0.5 | 1.031 | 1.281 | 1.5 | 1.75 | 1.969 | ... |

| 22 | 22 | 0.25 | ... | ... | 0.375 | ... | ... | 0.5 | ... | ... | .... | .... | .... | .... |

| 24 | 24 | 0.25 | 0.375 | 0.562 | 0.375 | 0.688 | 0.969 | 0.5 | 1.219 | 1.531 | 1.812 | 2.062 | 2.344 | .... |

| 26 | 26 | .... | .... | .... | 0.375 | .... | .... | 0.5 | .... | .... | .... | .... | .... | .... |

| 30 | 30 | 0.312 | 0.5 | 0.625 | 0.375 | .... | .... | 0.5 | .... | .... | .... | .... | .... | .... |

| 36 | 36 | 0.312 | 0.5 | 0.625 | 0.375 | 0.75 | .... | 0.5 | .... | .... | .... | .... | .... | .... |

| 40 | 40 | .... | .... | .... | 0.375 | .... | .... | 0.5 | .... | .... | .... | .... | .... | .... |

| 42 | 42 | …….. | …….. | …….. | 0.375 | …….. | …….. | 0.5 | …….. | …….. | …….. | …….. | …….. | …….. |

| 48 | 48 | …….. | …….. | …….. | 0.375 | …….. | …….. | 0.5 | …….. | …….. | …….. | …….. | …….. | …….. |

Santosh Pipe fitting Is Largest High Pressure Stainless Steel Flanges Supplier In India And Metric SS Tube Flanges Size Chart With Outside Diameter.

SS Flanges Bolt & Stud Chart

| Class 150 Flanges | Class 300 Flanges | Class 600 Flanges | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | # Bolts And Studs | Diameter of Bolts And Studs | Stud Length | # Bolts And Studs | Diameter of Bolts And Studs | Stud Length | # Bolts And Studs | Diameter of Bolts And Studs | Stud Length | |||

| 1/16 RF | RTJ | 1/16 RF | RTJ | 1/4 RF | RTJ | |||||||

| 1/2 | 4 | 0.50 | 2-1/4 | – | 4 | 0.50 | 2-1/2 | 3 | 4 | 0.50 | 3 | 3 |

| 3/4 | 4 | 0.50 | 2-1/2 | – | 4 | 0.63 | 3 | 3-1/2 | 4 | 0.63 | 3-1/2 | 3-1/2 |

| 1 | 4 | 0.50 | 2-1/2 | 3 | 4 | 0.63 | 3 | 3-1/2 | 4 | 0.63 | 3-1/2 | 3-1/2 |

| 1-1/4 | 4 | 0.50 | 2-3/4 | 3-1/4 | 4 | 0.63 | 3-1/4 | 3-3/4 | 4 | 0.63 | 3-3/4 | 3-3/4 |

| 1-1/2 | 4 | 0.50 | 2-3/4 | 3-1/4 | 4 | 0.75 | 3-1/2 | 4 | 4 | 0.75 | 4-1/4 | 4-1/4 |

| 2 | 4 | 0.63 | 3-1/4 | 3-3/4 | 8 | 0.63 | 3-1/2 | 4 | 8 | 0.63 | 4-1/4 | 4-1/4 |

| 2-1/2 | 4 | 0.63 | 3-1/2 | 4 | 8 | 0.75 | 4 | 4-1/2 | 8 | 0.75 | 4-3/4 | 4-3/4 |

| 3 | 4 | 0.63 | 3-1/2 | 4 | 8 | 0.75 | 4-1/4 | 4-3/4 | 8 | 0.75 | 5 | 5 |

| 3-1/2 | 8 | 0.63 | 3-1/2 | 4 | 8 | 0.75 | 4-1/4 | 5 | 8 | 0.88 | 5-1/2 | 5-1/2 |

| 4 | 8 | 0.63 | 3-1/2 | 4 | 8 | 0.75 | 4-1/2 | 5 | 8 | 0.88 | 5-3/4 | 5-3/4 |

| 5 | 8 | 0.75 | 3-3/4 | 4-1/4 | 8 | 0.75 | 4-3/4 | 5-1/4 | 8 | 1.00 | 6-1/2 | 6-1/2 |

| 6 | 8 | 0.75 | 4 | 4-1/2 | 12 | 0.75 | 4-3/4 | 5-1/2 | 12 | 1.00 | 6-3/4 | 6-3/4 |

| 8 | 8 | 0.75 | 4-1/4 | 4-3/4 | 12 | 0.88 | 5-1/2 | 6 | 12 | 1.13 | 7-1/2 | 7-3/4 |

| 10 | 12 | 0.88 | 4-1/2 | 5 | 16 | 1.00 | 6-1/4 | 6-3/4 | 16 | 1.25 | 8-1/2 | 8-1/2 |

| 12 | 12 | 0.88 | 4-3/4 | 5-1/4 | 16 | 1.13 | 6-3/4 | 7-1/4 | 20 | 1.25 | 8-3/4 | 8-3/4 |

| 14 | 12 | 1.00 | 5-1/4 | 5-3/4 | 20 | 1.13 | 7 | 7-1/2 | 20 | 1.38 | 9-1/4 | 9-1/4 |

| 16 | 16 | 1.00 | 5-1/4 | 5-3/4 | 20 | 1.25 | 7-1/2 | 8 | 20 | 1.50 | 10 | 10 |

| 18 | 16 | 1.13 | 5-3/4 | 6-1/4 | 24 | 1.25 | 7-3/4 | 8-1/4 | 20 | 1.63 | 10-3/4 | 10-3/4 |

| 20 | 20 | 1.13 | 6-1/4 | 6-3/4 | 24 | 1.25 | 8 | 8-3/4 | 24 | 1.63 | 11-1/4 | 11-1/2 |

| 24 | 20 | 1.25 | 6-3/4 | 7-1/4 | 24 | 1.50 | 9 | 10 | 24 | 1.88 | 13 | 13-1/4 |

| Class 900 Flanges | Class 1500 Flanges | Class 2500 Flanges | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | # Bolts And Studs | Diameter of Bolts And Studs | Stud Length | # Bolts And Studs | Diameter of Bolts And Studs | Stud Length | # Bolts And Studs | Diameter of Bolts And Studs | Stud Length | |||

| 1/4 RF | RTJ | 1/4 RF | RTJ | 1/4 RF | RTJ | |||||||

| 1/2 | 4 | 0.75 | 4-1/4 | 4-1/4 | 4 | 0.75 | 4-1/4 | 4-1/4 | 4 | 0.75 | 4-3/4 | 4-3/4 |

| 3/4 | 4 | 0.75 | 4-1/2 | 4-1/2 | 4 | 0.75 | 4-1/2 | 4-1/2 | 4 | 0.75 | 5 | 5 |

| 1 | 4 | 0.88 | 5 | 5 | 4 | 0.88 | 5 | 5 | 4 | 0.88 | 5-1/2 | 5-1/2 |

| 1-1/4 | 4 | 0.88 | 5 | 5 | 4 | 0.88 | 5 | 5 | 4 | 1.00 | 6 | 6 |

| 1-1/2 | 4 | 1.00 | 5-1/2 | 5-1/2 | 4 | 1.00 | 5-1/2 | 5-1/2 | 4 | 1.13 | 6-3/4 | 6-3/4 |

| 2 | 8 | 0.88 | 5-3/4 | 5-3/4 | 8 | 0.88 | 5-3/4 | 5-3/4 | 8 | 1.00 | 7 | 7 |

| 2-1/2 | 8 | 1.00 | 6-1/4 | 6-1/4 | 8 | 1.00 | 6-1/4 | 6-1/4 | 8 | 1.13 | 7-3/4 | 8 |

| 3 | 8 | 0.88 | 5-3/4 | 5-3/4 | 8 | 1.13 | 7 | 7 | 8 | 1.25 | 8-3/4 | 9 |

| 4 | 8 | 1.13 | 6-3/4 | 6-3/4 | 8 | 1.25 | 7-3/4 | 7-3/4 | 8 | 1.50 | 10 | 10-1/4 |

| 5 | 8 | 1.25 | 7-1/2 | 7-1/2 | 8 | 1.50 | 9-3/4 | 9-3/4 | 8 | 1.75 | 11-3/4 | 12-1/4 |

| 6 | 12 | 1.13 | 7-1/2 | 7-3/4 | 12 | 1.38 | 10-1/4 | 10-1/2 | 8 | 2.00 | 13-1/2 | 14 |

| 8 | 12 | 1.38 | 8-3/4 | 8-3/4 | 12 | 1.63 | 11-1/2 | 11-3/4 | 12 | 2.00 | 15 | 15-1/2 |

| 10 | 16 | 1.38 | 9-1/4 | 9-1/4 | 12 | 1.88 | 13-1/4 | 13-1/2 | 12 | 2.50 | 19-1/4 | 20 |

| 12 | 20 | 1.38 | 10 | 10 | 16 | 2.00 | 14-3/4 | 15-1/4 | 12 | 2.75 | 21-1/4 | 22 |

| 14 | 20 | 1.50 | 10-3/4 | 11 | 16 | 2.25 | 16 | 16-3/4 | – | – | – | – |

| 16 | 20 | 1.63 | 11-1/4 | 11-1/2 | 16 | 2.50 | 17-1/2 | 18-1/2 | – | – | – | – |

| 18 | 20 | 1.88 | 12-3/4 | 13-1/4 | 16 | 2.75 | 19-1/2 | 20-3/4 | – | – | – | – |

| 20 | 20 | 2.00 | 13-3/4 | 14-1/4 | 16 | 3.00 | 21-1/4 | 22-1/4 | – | – | – | – |

| 24 | 20 | 2.50 | 17-1/4 | 18 | 16 | 3.50 | 24-1/4 | 25-1/2 | – | – | – | – |

Gaskets For ASTM A182 Stainless Steel Flanges

| NPS | Gasket I.D. |

Gasket O.D. | ||||

|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | ||

| 1/2 | 0.84 | 1.875 | 2.125 | 2.125 | 2.125 | 2.50 |

| 3/4 | 1.06 | 2.25 | 2.625 | 2.625 | 2.625 | 2.75 |

| 1 | 1.31 | 2.625 | 2.875 | 2.875 | 2.875 | 3.125 |

| 1 1/4 | 1.66 | 3 | 3.25 | 3.25 | 3.25 | 3.50 |

| 1 1/2 | 1.91 | 3.375 | 3.75 | 3.75 | 3.75 | 3.875 |

| 2 | 2.38 | 4.125 | 4.375 | 4.375 | 4.375 | 5.625 |

| 2 1/2 | 2.88 | 4.875 | 5.125 | 5.125 | 5.125 | 6.50 |

| 3 | 3.50 | 5.375 | 5.875 | 5.875 | 5.875 | 6.625 |

| 4 | 4.50 | 6.875 | 7.125 | 7.00 | 7.625 | 8.125 |

| 5 | 5.56 | 7.75 | 8.50 | 8.375 | 9.50 | 9.75 |

| 6 | 6.62 | 8.75 | 9.875 | 9.75 | 10.50 | 11.375 |

| 8 | 8.62 | 11 | 12.125 | 12.00 | 12.625 | 14.125 |

| 10 | 10.75 | 13.375 | 14.25 | 14.125 | 15.75 | 17.125 |

| 12 | 12.75 | 16.125 | 16.625 | 16.50 | 18.00 | 19.625 |

SS Forged Flanges Tolerances

| ASME B16.5 | Tolerance | |

|---|---|---|

| A | Outside Diameter (O.D.) |

|

| D | Inside Diameter |

|

| B | Diameter of contact face |

|

| J | Diameter of hub at base |

|

| H | Diameter of hub at point of welding |

|

| P | Drilling |

|

| Eccentricity of bolt circle with respect to facing |

|

|

| C | Thickness |

|

| K | Length of hub |

|

Reliable Types Stainless Steel Flange Manufacturer In India

Stainless Steel Slip On Flange

Stainless Steel Socket Weld Flange

Stainless Steel Blind Flange

Stainless Steel Weld Neck Flange

Stainless Steel Threaded Flange

Stainless Steel Lap Joint Flange

Stainless Steel Long Weld Neck Flanges

Stainless Steel Spectacle Blind Flange

Stainless Steel Spade Flange

Stainless Steel Flange Ring Spacer

Stainless Steel Nipo Flange

Nipo Flange

Stainless Steel Flange olet

Stainless Steel Bleed Ring Flange

Stainless Forged Flanges

Stainless Steel Plate Flange

Stainless Steel Ring Type Joint Flange

Stainless Steel Raised Face Flange

Stainless Steel Tongue and Groove Flange

Stainless Steel Male and Female Flange

Stainless Steel Reducing Flange

Stainless Steel Square Flange

Stainless Steel High hub Blind Flange

Stainless Steel Orifice Flanges

Stainless Steel Puddle Flange

Stainless Steel Expander Flange

Stainless Steel Flat Flange

Stainless Steel Flange Adapter

Stainless Steel Flange Gasket

Stainless Steel Hydraulic Sae Flanges

Stainless Steel Anchor Flange

Some Of The Countries We Have Supplied Various Types Of Industrial SS Pipe Flanges Recently:

| 2 Inch, Class 300, SCH 40, ASME B16.5, Stainless Steel Flanges | South Africa, Bahrain, Singapore, Singapore |

| Class 1500, 2 Inch, ANSI B16.47, ASTM A182 SS Flanges | Philippines, UK, Australia, Nigeria |

| 12 Inch, SCH 40, RF, 150 LB, Large Diameter Steel Flanges | Oman, UAE, Hong Kong, Malaysia |

| EN1092-2 Type 11, RF, PN16, DN80, SS Screwed Flanges | Chile, Singapore, Iran, Italy |

| DN 200, Class 300, RF, STD, Forged, High Pressure Pipe Flanges | United Arab Emirates (UAE), Norway, Turkey, Malaysia |

| SCH 40S, 2 1/2 Inch, Forged, B16.5, SS Header Flanges | United Kingdom -UK, Malaysia, Europe, UAE |

| SA-516 Grade 70, ASME b16.5, Custom Stainless Exhaust Flanges | Dammam -KSA, Belgium, Philippines, Indonesia. |

| 13 Inch, STD Bore, BS 10 Class E, Stainless Steel Stub End Flanges | Qatar, Thailand, Europe, France. |

| 10 Inch, RF, ASTM A182, 300#, ASME B16.5, Industrial Flanges | Malaysia, Thailand, Germany, Czechia |

| 3 In, Raised Face, 300LB, SCH 10, Stainless Steel Welded Flanges | Finland, Bangladesh, Malaysia, USA |

| Class 150, 2 Inch, SCH 80, FF, Forged Steel Flanges | Saudi Arabia (KSA), Kuwait, South Africa, Brazil |

| 6 Inch, SCH 20, RF Ends, Class 150/300, Stainless Metric Flanges | Netherlands, Russia, Malaysia, Dubai |

| Class 900, 8 Inch, SCH 120, RF, SA182 SS Flanges | Egypt, UK, Mexico, Spain |

| RF, 5 Inch, 150 LB, ASME B16.5, Stainless Steel Split Flanges | UK, Ellington -United States, Poland, Canada |

| ASME B16.47, 12 Inch, RF, Stainless Steel Class 150 Flanges | Canada, Malaysia, Philippines, Singapore |

| 1 To 18 Inch, RF, Class 150 To 2500, SS Flanges | Japan, Romania, Europe, Malaysia |

| 30 Inch, DN 200, 300#, RF, STD, API 6, forged SS Flanges | Sweden, China, Malaysia, Colombia |