ASTM A234 WPB Pipe Fittings

A234 Steel Buttweld Fittings and SA 234 Gr WPB Material manufacturer in India.

ASTM A234 WPB Pipe Fittings

SA234 WPB Material Specification

A234 Wpb Chemical Composition

Table of contents

- What Does WPB Mean On Pipe Fittings?

- What Is SA234 Material?

- What Is ASTM A234 Grade WPB?

- ASTM A234 WPB Specification

- ASTM A234 WPB Fittings Dimensions

- ASTM A234 WPB Fittings Weight

- A234 WPB Equivalent

- Astm A234 WPB Chemical Composition

- A234 Gr WPB Mechanical Properties

- A234 WPB Carbon Steel Tensile Requirements

- Astm A234 WPB Pressure Rating

- SA234 WPB Heat Treatment

- ASTM A234 WPB Pipe Fittings Tolerance Formula

- A234 WPB Gasket Material

- A234 WPB Hardness

- What Is The Difference Between A105 And A234

- Accept All Small And Large Orders Types Of ASTM A234 WPB Pipe Fittings

Check A234 WPB Carbon Steel Fittings Price List and ASTM A234 Gr WPB Fittings Dimensions/ Weight Chat.

What Does WPB Mean On Pipe Fittings?

ASTM A234 WPB Pipe Fittings are made up of wrought carbon steel that they are very strong and can be applied in high strength requirements. The ASTM A234 WPB are heat treated and then allowed to cool rapidly. The chemical composition of the ASTM A234 WPB Fittings include carbon, manganese, phosphorus, sulfur, silicon, chromium, molybdenum, nickel, copper and other trace elements such as vanadium. The great composition of SA234 WPB makes it suitable for high pressure and high temperature applications.

What Is SA234 Material?

The SA234 Material are also highly corrosion resistant. Due to the addition of copper in the SA234 WPB Material, the A234 WPB Carbon Steel is also very much resistant against sulfuric acid corrosion. This makes the A234 WPB Carbon Steel Fittings applicable in various chemical processes which involve the sulfuric acid in the flow. The A234 WPB standards govern the nominal sizes of the ASTM A234 WPB Fittings.

What Is ASTM A234 Grade WPB?

The ASTM A234 Grade WPB nominal sizes range from ½ inches to 48 inches. The applications of A234 WPB range widely. They include thermal power plants, nuclear power generation systems, petroleum refineries, catalytic recovery systems, paper mills and equipment, gas and water pipe lines, irrigation engineering and more. The high strength, excellent conductivity and the impeccable finish of the A234 WPB make it used in a wide range of applications.

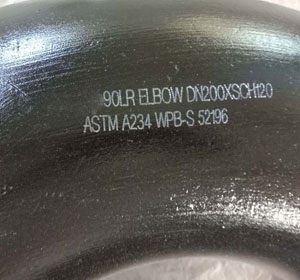

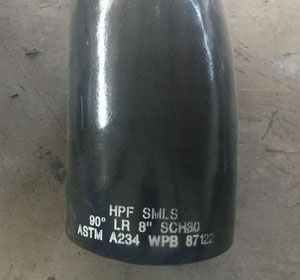

ASTM A234 WPB Specification

| Specification: | ASTM A234 WPB Pipe Fittings |

| Schedule: | Schedule 5 TO Schedule XXS. |

| Size: | Normal Pipe Size (NPS) 1⁄₂ to Normal Pipe Size (NPS) 48” |

| Type: | Butt Weld (BW), Seamless (SMLS) Welded |

| Standard | EN, ISO, DIN, JIS, NPT |

| Type | Elbow, Stub End, Bend, Tee, Reducer, Cap, Adapter, Wye, Cross, |

| Connection Type | Threaded/ Clamp End / End Bell / Weld/ Flange/ |

| Pressure-Temperature Class | 150LB, 300LB, 600LB, 1500LB, 2500LB. |

| Thickness: | Sch 5S, 20S, S10, S20, S30, 10S, S80, S100, S120, STD, 40S, S40, S60, XS, 80S, S140, S160, XXS and etc. |

| Type Of Dimension: | BS1640, EN 10253 - 4, DIN 2605, JIS B2312, ANSI B16.9, MSS SP-75, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2313 |

ASTM A234 WPB Fittings Dimensions

| NPS | O.D. | 90 Degree Elbow | 45 Degree Elbow | 180 Degree Return | ||||

|---|---|---|---|---|---|---|---|---|

| (inch) | Long Radius Elbow | Short Radius | Long Radius Elbow | Long Radius Elbow | ||||

| (millimeter) | (inch) | Center to Face (inch) |

Center to Face (inch) |

Center to Face (inch) |

Radius (inch) |

Center to Center (inch) |

Back to face (inch) |

|

| 1/2 | 21.3 | 0.840 | 1 1/2 | – | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | – | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

| NPS | O.D. | Pipe End Caps | Straight Tee | Straight Cross | Long / Short Stub Ends | |||

|---|---|---|---|---|---|---|---|---|

| (inch.) | (millimeter) | (inch.) | Length (inch.) |

Center to End (inch.) |

Center to End (inch.) |

Lap Diameter (inch.) |

Long Length (inch.) |

Short Length (inch.) |

| 1/2 | 21.3 | 0.840 | 1 | 1 | – | 1 3/8 | 3 | 2 |

| 3/4 | 26.7 | 1.050 | 1 | 1 1/8 | – | 1 11/16 | 3 | 2 |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 1/2 | 1 1/2 | 2 | 4 | 2 |

| 1 1/4 | 42.2 | 1.660 | 1 1/2 | 1 7/8 | 1 7/8 | 2 1/2 | 4 | 2 |

| 1 1/2 | 48.3 | 1.900 | 1 1/2 | 2 1/4 | 2 1/4 | 2 7/8 | 4 | 2 |

| 2 | 60.3 | 2.375 | 1 1/2 | 2 1/2 | 2 1/2 | 3 5/8 | 6 | 2 1/2 |

| 2 1/2 | 73.0 | 2.875 | 1 1/2 | 3 | 3 | 4 1/8 | 6 | 2 1/2 |

| 3 | 88.9 | 3.500 | 2 | 3 3/8 | 3 3/8 | 5 | 6 | 2 1/2 |

| 3 1/2 | 101.6 | 4.000 | 2 1/2 | 3 3/4 | 3 3/4 | 5 1/2 | 6 | 3 |

| 4 | 114.3 | 4.500 | 2 1/2 | 4 1/8 | 4 1/8 | 6 3/16 | 6 | 3 |

| 5 | 141.3 | 5.563 | 3 | 4 7/8 | 4 7/8 | 7 5/16 | 8 | 3 |

| 6 | 168.3 | 6.625 | 3 1/2 | 5 5/8 | 5 5/8 | 8 1/2 | 8 | 3 1/2 |

| 8 | 219.1 | 8.625 | 4 | 7 | 7 | 10 5/8 | 8 | 4 |

| 10 | 273.1 | 10.750 | 5 | 8 1/2 | 8 1/2 | 12 3/4 | 10 | 5 |

| 12 | 323.9 | 12.750 | 6 | 10 | 10 | 15 | 10 | 6 |

ASTM A234 WPB Fittings Weight

|

DN (Normal Pipe Sizes) |

Sch 10S |

Sch 40S |

Sch 80S | ||||||

|

90 Deg Elbow | 45 Deg Elbow | Equal Pipe tee |

90 Deg Elbow | 45 Deg Elbow |

Equal Pipe tee | 90 Deg Elbow | 45 Deg Elbow |

Equal Pipe Tee | |

|

8 |

0.02 |

0.01 |

0.03 |

0.03 |

0.02 |

0.06 |

0.04 |

0.03 |

0.07 |

|

10 |

0.03 |

0.02 |

0.05 |

0.03 |

0.02 |

0.03 |

0.06 |

0.04 |

0.09 |

|

15 |

0.06 |

0.03 |

0.09 |

0.08 |

0.04 |

0.10 |

0.10 |

0.05 |

0.14 |

|

20 |

0.07 |

0.03 |

0.13 |

0.08 |

0.04 |

0.17 |

0.11 |

0.05 |

0.20 |

|

25 |

0.14 |

0.08 |

0.28 |

0.15 |

0.11 |

0.29 |

0.22 |

0.14 |

0.38 |

|

32 |

0.23 |

0.11 |

0.49 |

0.26 |

0.17 |

0.59 |

0.40 |

0.23 |

0.68 |

|

40 |

0.30 |

0.17 |

0.68 |

0.40 |

0.23 |

0.86 |

0.51 |

0.29 |

1.02 |

|

50 |

0.50 |

0.25 |

0.85 |

0.70 |

0.4 |

1.28 |

0.91 |

0.59 |

1.59 |

|

65 |

0.85 |

0.48 |

1.41 |

1.40 |

0.77 |

2.19 |

1.81 |

0.99 |

3.13 |

|

80 |

1.25 |

0.63 |

1.77 |

2.20 |

1.08 |

3.31 |

2.97 |

1.50 |

4.45 |

|

90 |

1.70 |

0.75 |

2.67 |

2.83 |

1.42 |

4.08 |

4.00 |

2.00 |

5.44 |

|

100 |

2.10 |

1.08 |

3.46 |

4.47 |

2.09 |

5.27 |

6.18 |

2.81 |

7.71 |

|

150 |

5.45 |

2.72 |

8.07 |

10.89 |

5.44 |

10.99 |

16.32 |

8.16 |

13.61 |

|

200 |

10.20 |

5.33 |

15.65 |

21.54 |

10.77 |

20.91 |

33.11 |

16.56 |

28.12 |

|

250 |

18.15 |

9.75 |

26.46 |

38.56 |

19.27 |

35.38 |

51.71 |

25.86 |

49.90 |

|

300 |

25.80 |

13.62 |

39.46 |

59.42 |

29.71 |

62.14 |

79.38 |

39.69 |

83.91 |

|

DN (Normal Pipe Sizes) |

Sch 10S |

Sch 40S |

Sch 80S | ||||||

| Con Pipe Reducer | Ecc Pipe Reducer | Reducing/ Unequal Tee | Con Pipe Reducer | Ecc Pipe Reducer | Reducing/ Unequal Tee | Con Pipe Reducer | Ecc Pipe Reducer | Reducing/ Unequal Tee | |

|

40x.25 |

0.19 |

0.19 |

0.60 |

0.26 |

0.26 |

0.76 |

0.34 |

0.34 |

0.90 |

|

50x25 |

0.28 |

0.28 |

0.73 |

0.40 |

0.40 |

1.10 |

0.54 |

0.54 |

1.37 |

|

50x40 |

0.31 |

0.31 |

0.76 |

0.45 |

0.45 |

1.15 |

0.59 |

0.59 |

1.43 |

|

80x.50 |

0.55 |

0.55 |

1.56 |

1.00 |

1.00 |

2.91 |

1.79 |

1.79 |

3.91 |

|

100x50 |

0.78 |

0.78 |

2.94 |

1.50 |

1.50 |

4.48 |

1.95 |

1.95 |

6.55 |

|

100x80 |

0.87 |

0.87 |

3.04 |

1.74 |

1.74 |

4.64 |

2.33 |

2.33 |

6.79 |

|

150x80 |

1.82 |

1.82 |

6.86 |

3.95 |

3.95 |

9.68 |

5.51 |

5.51 |

11.57 |

|

150x100 |

1.96 |

1.96 |

7.10 |

4.07 |

4.07 |

11.94 |

5.96 |

5.96 |

11.97 |

|

200x100 |

3.01 |

3.01 |

13.46 |

6.55 |

6.55 |

17.98 |

9.23 |

9.23 |

24.18 |

|

200x150 |

3.19 |

3.19 |

14.08 |

6.74 |

6.74 |

18.82 |

10.12 |

10.12 |

25.31 |

Check A234 WPB Equivalent/ Hardness And ASTM A234 WPB Pressure Rating, Buy Directly From Carbon Steel A234 WPB Seamless/ Welded Pipe Fittings Supplier In India.

A234 WPB Equivalent

| Pipe | Fittings | Flanges | Valves | Bolts & Nuts |

|---|---|---|---|---|

| ASTM A106 Gr A | ASTM A234 Gr WPA | ASTM A105 | ASTM A216 Gr WCB | A193 Gr B7 A194 Gr 2H |

| ASTM A106 Gr B | A234 Gr WPB | ASTM A105 | ASTM A216 Gr WCB | |

| ASTM A106 Gr C | ASTM A234 Gr WPC | ASTM A105 | ASTM A216 Gr WCB |

- The sum of Cu, Ni, Cr, and Mo shall not exceed 1.00%.

- The sum of Cr and Mo shall not exceed 0.32%.

- For each reduction of 0.01% below the specified C max., an increase of 0.06% Mn above the specified max. will be permitted, up to a max. of 1.35%.

- The max. carbon equivalent (C.E.) shall be 0.50, based on heat analysis and the formula C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

A234 Gr WPB Mechanical Properties

| Item | Tensile Strength (KSI) | Yield Strength (KSI) |

| WPB | 60 | 35 |

ASTM A234 WPB Chemical Composition And Check Difference Between A105 VS A234 Buttweld Fittings.

Astm A234 WPB Chemical Composition

| Gr. | C | Mn | P | S | Si | |

| WPB | 0.3 | 0.29-1.06 | 0.05 | 0.058 | 0.1 minimum | |

| Gr. | Cr | Mo | Ni | Cu | V | Nb |

| WPB | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

A234 WPB Carbon Steel Tensile Requirements

|

Gr. and Marking Symbol

|

WPB

|

WPC, WP11 CL1, WP12 CL2

|

WP1

|

WP11 CL1, WP22 CL1, WP5 CL1, WP9 CL1

|

WPR

|

WP11 CL3, WP22 CL3, WP2 CL3, WP9 CL3

|

WP91

|

WP911

|

WP12 CL1

|

|

Tensile strength, range Ksi [MPa]

|

60-95 [415-655] |

70-95 [485-655]

|

55-80 [380-550]

|

60-85 [415-585] |

63-88 [435-605]

|

75-100 [520-690]

|

85-110 [585-760]

|

90-120 [620-840]

|

60-85 [415-585]

|

|

Yield strength, minimum, Ksi [MPa] (0.2% offset or 0.5% extension- under-load)

|

35 [240]

|

40 [275]

|

30 [205]

|

30 [205]

|

46 [315]

|

45 [310]

|

60 [415]

|

64 [440]

|

32 [220]

|

Astm A234 WPB Pressure Rating

| Pressure-Temperature ratings for ASTM A234 WPB Pipe Fittings (psig) | |||||

|---|---|---|---|---|---|

| Temperature Ratings | Pressure Class | ||||

| 150 | 300 | ||||

| 1/4 - 1 inch. | 1 1/4 - 2 inch. | 2 1/2 - 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | - | 935 | 750 | 560 |

| 450 | 232 | - | 725 | 600 | 475 |

| 500 | 260 | - | 510 | 450 | 385 |

| 550 | 288 | - | 300 | 300 | 300 |

SA234 WPB Heat Treatment

ASTM A234 WPB Pipe Fittings are cooled to a temperature below the critical range under suitable conditions after forming at an elevated temperature, to prevent injurious defects caused by too rapid cooling. Heat treatment temperatures for ASTM A234 WPB specified are metal (part) temperatures.

ASTM A234 WPB Pipe Fittings Tolerance Formula

| ASTM A234 WPB Pipe Fittings Tolerance | 90 Degree & 45 Degree Elbows & Tees |

Reducers & Lap Joint Stub End |

Pipe Caps | |||

| ASTM A234 WPB (Normal Pipe Size) | O. D. at Bevel |

I. D. at End |

Wall Thick. T | Center-to-End Dimension A ,C ,B |

Over-all Length H |

Over-all Length F |

| 1/2 to 2-1/2 | +0.06 | Not less than 87.5% of nominal thickness |

+/- 0.06 | +/- 0.06 | +/- 0.12 | |

| -0.03 | ||||||

| 3 to 3-1/2 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 4 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 5 to 8 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.25 | |

| 10 to 18 | +0.16 | +/- 0.12 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.12 | ||||||

| 20 to 24 | +0.25 | +/- 0.19 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.19 | ||||||

| 26 to 30 | +0.25 | +/- 0.19 | +/- 0.12 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

| 32 to 48 | +0.25 | +/- 0.19 | +/- 0.19 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

A234 WPB Gasket Material

| NPS | Gasket I.D. |

Gasket O.D. (Outsdie Daimeter) | ||||

|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | ||

| 1/2 | 0.84 | 1.875 | 2.125 | 2.125 | 2.125 | 2.50 |

| 3/4 | 1.06 | 2.25 | 2.625 | 2.625 | 2.625 | 2.75 |

| 1 | 1.31 | 2.625 | 2.875 | 2.875 | 2.875 | 3.125 |

| 1 1/4 | 1.66 | 3 | 3.25 | 3.25 | 3.25 | 3.50 |

| 1 1/2 | 1.91 | 3.375 | 3.75 | 3.75 | 3.75 | 3.875 |

| 2 | 2.38 | 4.125 | 4.375 | 4.375 | 4.375 | 5.625 |

| 2 1/2 | 2.88 | 4.875 | 5.125 | 5.125 | 5.125 | 6.50 |

| 3 | 3.50 | 5.375 | 5.875 | 5.875 | 5.875 | 6.625 |

| 4 | 4.50 | 6.875 | 7.125 | 7.00 | 7.625 | 8.125 |

| 5 | 5.56 | 7.75 | 8.50 | 8.375 | 9.50 | 9.75 |

| 6 | 6.62 | 8.75 | 9.875 | 9.75 | 10.50 | 11.375 |

| 8 | 8.62 | 11 | 12.125 | 12.00 | 12.625 | 14.125 |

| 10 | 10.75 | 13.375 | 14.25 | 14.125 | 15.75 | 17.125 |

| 12 | 12.75 | 16.125 | 16.625 | 16.50 | 18.00 | 19.625 |

A234 WPB Hardness

A234 WPB Carbon Steel is made from A106 gr B and have an imposed value of 197 HB max.

What Is The Difference Between A105 And A234

ASTM A234 WPB Pipe Fittings are made up of wrought carbon steel that they are very strong and can be applied in high strength requirements. The ASTM A234 WPB are heat treated and then allowed to cool rapidly.

Carbon Steel Forged Fittings are pipe fittings made out of A105 Material. These are produced in annealed, normalized, normalized and tempered or quenched and tempered conditions.

Santosh Pipe Fitting is a renowned A234 WPB Fittings Manufacturer. We produce all types of WPB Carbon Steel fittings. Our products range from ½ inches to 60 inches of piping. We produce different material made pipe fittings such as the A234 WPB Carbon Steel fittings. The weldabe pressure grade B ASTM A234 WPB is used in applications that require seamless pipe fittings or welded pipe fittings. ASTM A234 WPB Fittings range in type, shape and size. There are unions, couplings, elbows, adapters and so on.

Accept All Small And Large Orders Types Of ASTM A234 WPB Pipe Fittings

ASTM A234 WPB Elbow

ASTM A234 WPB Tee

ASTM A234 WPB Reducer

ASTM A234 WPB End Cap

ASTM A234 WPB Bend

An Oldest ASTM A234 WPB Fittings Suppliers In India, Recently Shipped To The Following Countries

| SCH STD, 8 Inch × 4 Inch, ASTM A234 WPB Fittings | Kuwait, Brazil, South Africa, Saudi Arabia (KSA) |

| SCH 60, 6 X 3 Inch, ASTM A234 Gr WPB Fittings | Australia, Philippines, Nigeria, UK |

| SCH 80, BW, 10 X 8 Inch, Carbon Steel A234 WPB Fittings | Hong Kong, Oman, Malaysia, UAE |

| SCH STD, 10 Inch, Buttweld A234 WPB Fittings | Bahrain, Singapore, South Africa |

| SCH 40, 250 X 80 millimeter, A234 WPB Weld Fittings | Chile, Singapore, Italy, Iran |

| SCH 160, 2 Inch, BW End, A234 WPB Carbon Steel Fittings | Norway, Malaysia, Turkey, United Arab Emirates (UAE) |

| 8 Inch, Galvanized, SA A234 Grade WPB Seamless Fittings | Belgium, Philippines, Dammam -KSA, Indonesia. |

| SCH 60, 12 Inch, Carbon Steel A234 WPB Fittings | Malaysia, Philippines, Canada, Singapore |

| Butt Weld, 14 Inch, SCH 120, ASTM A234 Grade WPB Fittings | Romania, Japan, Europe, Malaysia |

| Black, 6 Inch, SCH 40, ASTM A234 WPB Seamless Pipe Fittings | Sweden, China, Colombia, Malaysia |

| Seamless, 12 Inch, SCH 60, A234 WPB Material | Russia, Dubai, Netherlands, Malaysia |

| 12 Inch, SCH 80, O.D. 300mm, A234 WPB Smls Pipe Fittings | UK, Mexico, Egypt, Spain |

| Black Coating, 4 Inch, BW Ends, A234 WPB Welded Fittings | Poland, Canada, Ellington -United States, UK |

| Sch 80, 4 Inch, ASME B16.11, SA234 WPB Material | Europe, UAE, United Kingdom -UK, Malaysia |

| SCH 40, 18 Inch, 2032mm, ASTM A234 WPB Buttweld Fittings | Europe, France, Thailand, Qatar |

| AWWA C208, DN750, Carbon Steel SA234 WPB Fittings | Malaysia, Germany, Czechia, Thailand |

| 6 Inch, SCH 40, ASME B16.9, ASTM A234 WPB Fittings | USA, Bangladesh, Finland, Malaysia |